Every successful construction or manufacturing project begins long before the first beam is laid or the first prototype is printed. It starts with a critical decision that dictates the longevity, safety, and budget of the entire endeavor: material selection.

Choosing the wrong material is more than just a minor inconvenience. It can lead to catastrophic structural failures, ballooning maintenance costs, and project delays that eat into your bottom line.

Conversely, getting it right means your project will stand the test of time, function exactly as intended, and remain within budget.

The challenge lies in the sheer volume of options available. From traditional hardwoods and reinforced concrete to advanced composites and high-strength alloys, the marketplace is flooded with possibilities.

Navigating this landscape requires a strategic approach that balances physical properties with practical logistics.

Whether you are an engineer, an architect, or a project manager, understanding how to match material properties to project demands is a fundamental skill.

1. Define the Environmental Conditions

Before looking at catalogs or price lists, you must analyze where the final product will live. The environment is the primary aggressor against any material, and ignoring it is a recipe for premature degradation.

Outdoor vs. Indoor Exposure

Materials exposed to the elements require robust protection. UV radiation can make certain plastics brittle over time, while moisture is the nemesis of untreated steel and wood.

If your project is located in a coastal region, saltwater corrosion becomes a major factor, necessitating the use of stainless steel, marine-grade aluminum, or galvanized coatings.

Temperature Fluctuations

Thermal expansion and contraction can tear a structure apart if not accounted for. In regions with extreme temperature swings—hot days and freezing nights—materials need to have compatible coefficients of thermal expansion.

For instance, combining concrete and steel works well because they expand and contract at similar rates, whereas mixing incompatible materials can result in warping or cracking.

2. Analyze Mechanical Properties

Once you understand the environment, you must determine what the material actually needs to do. This involves a deep dive into mechanical properties.

Strength and Load Bearing

You need to distinguish between different types of strength. Tensile strength refers to how well a material resists being pulled apart, while compressive strength measures how well it withstands being squeezed.

Concrete has excellent compressive strength but poor tensile strength, which is why it is often reinforced with steel rebar.

Ductility and Malleability

In seismic zones or machinery that endures vibration, you don’t always want the hardest material. Hardness often correlates with brittleness.

Sometimes, you need a material that can deform slightly under stress without snapping—a property known as ductility.

Steel is a prime example of a material that offers a balance of strength and ductility, allowing it to absorb energy without catastrophic failure.

3. Consider Lifecycle Costs vs. Upfront Costs

Budget is always a driving factor, but focusing solely on the initial purchase price is a common mistake. Value engineering requires looking at the Total Cost of Ownership (TCO).

Initial Procurement

Some materials are cheap to buy but expensive to work with. A low-cost metal that requires specialized welding techniques or difficult machining might end up costing more in labor hours than a premium, easier-to-work-with alternative.

Maintenance and Durability

Consider the long game. Untreated timber might be cheaper than composite decking upfront, but the timber requires annual staining and sealing. Over twenty years, the composite material—which requires zero maintenance—often ends up being the cheaper option. Similarly, using a corrosion-resistant alloy might cost 20% more initially but saves the cost of repainting or replacing corroded parts five years down the road.

4. Availability and Logistics

You might identify the perfect material—a specific alloy that is lightweight, strong, and corrosion-resistant. However, if that material has a six-month lead time and has to be shipped from overseas, it might not be the right choice for a project with a tight deadline.

Supply chain reliability is just as important as material properties. You need to ensure that the materials you specify are accessible when you need them. This is where local sourcing becomes a strategic advantage. Working with regional suppliers reduces shipping costs and mitigates the risk of global supply chain disruptions.

For instance, if you are managing a large-scale commercial build in the Mountain West, securing a partner for steel supply in Salt Lake City ensures you have access to critical structural components without the delays associated with cross-country transit.

Local availability often trumps theoretical perfection; a readily available standard grade of steel is often a better choice than a perfect exotic alloy that arrives three months late.

5. Sustainability and Regulatory Compliance

Modern construction and manufacturing standards are increasingly governed by sustainability goals and strict regulations.

Eco-Friendly Options

Clients are prioritizing green building certifications like LEED. This drives the demand for materials with high recycled content or those that are easily recyclable at the end of their life.

Steel and aluminum are excellent in this regard, as they can be recycled indefinitely without losing their properties.

Code Compliance

Never overlook local building codes. Fire resistance ratings, toxicity levels, and seismic standards are non-negotiable. Using a material that doesn’t meet specific ASTM or ISO standards for your region will lead to inspection failures and costly rework.

6. Aesthetic Requirements

While function usually dictates form, aesthetics cannot be ignored, especially in architectural projects. The material must align with the visual vision of the design.

Finish and Texture

Does the project call for a sleek, modern industrial look, or something warm and organic? Exposed steel beams offer a specific architectural language, while stone or timber conveys something entirely different.

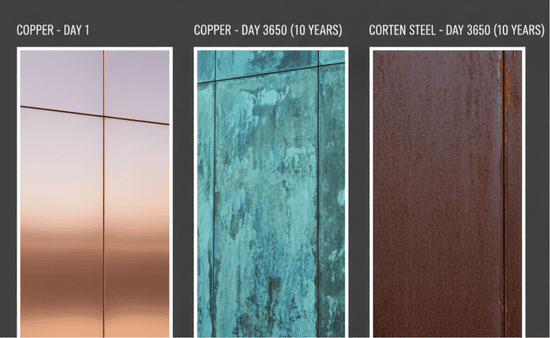

Aging

Consider how the material looks on day one versus day one thousand. Copper develops a green patina; untreated cedar turns gray; corten steel develops a protective rust layer.

You must ensure the client understands and desires these changes, or select materials that maintain their original appearance through coatings and treatments.

Making the Final Decision

Selecting the right material is a balancing act. It requires weighing the physical demands of the load against the chemical attacks of the environment, all while keeping an eye on the budget and the clock.

There is rarely a single “perfect” material. Instead, there is an optimal compromise that satisfies the most critical constraints of your project.

By methodically assessing the environment, mechanical needs, costs, and logistics, you can make informed decisions that ensure safety and success.

Don’t hesitate to lean on experts during this process. Whether you are consulting with structural engineers or discussing availability with your vendor for steel supply in Salt Lake City, gathering professional input early in the design phase can save you from making expensive assumptions. The right material is out there; you just have to ask the right questions to find it.