In the fast-paced and high-stakes world of oilfield operations, efficiency isn’t just a goal—it’s a necessity. With rising operational costs, increasing competition, and the pressure to meet strict production targets, optimizing your oilfield service company is critical for sustained profitability.

From technology adoption to workforce management, there are strategic ways to boost productivity while keeping expenses in check. Here’s a closer look at actionable tips to make your oilfield operations smarter, more efficient, and more profitable.

1. Embrace Modern Technology

One of the most effective ways to increase productivity in oilfield services is to integrate modern technology into daily operations. Tools such as real-time monitoring systems, predictive maintenance software, and automated drilling controls can significantly reduce downtime and operational inefficiencies.

For instance, using digital dashboards allows managers to track equipment performance, crew activity, and supply chain status in real time, ensuring quick decision-making and proactive problem-solving.

Investing in advanced technology also helps reduce human error, which is a common source of delays and cost overruns in the field. While upfront costs may seem high, the long-term savings from optimized operations and improved safety far outweigh the initial investment.

2. Optimize Resource Allocation

Proper resource allocation is crucial for maximizing efficiency in oilfield operations. This means ensuring that the right equipment and personnel are available at the right time, and that every asset is utilized to its full potential.

An underused piece of equipment sitting idle not only wastes capital but also adds unnecessary operational costs.

Scheduling software and asset management systems can help coordinate equipment usage, crew assignments, and maintenance activities. By having a clear view of all resources, managers can make informed decisions, reduce bottlenecks, and ensure operations run smoothly without interruptions.

3. Focus on Workforce Training

Your team is your greatest asset. Investing in regular training programs for field personnel ensures that your workforce remains skilled, knowledgeable, and adaptable.

Training should cover both technical skills and safety procedures, with an emphasis on efficiency and best practices.

A well-trained crew can identify potential issues before they become major problems, work more efficiently with complex equipment, and reduce the likelihood of accidents. This not only enhances productivity but also minimizes costly downtime and equipment damage.

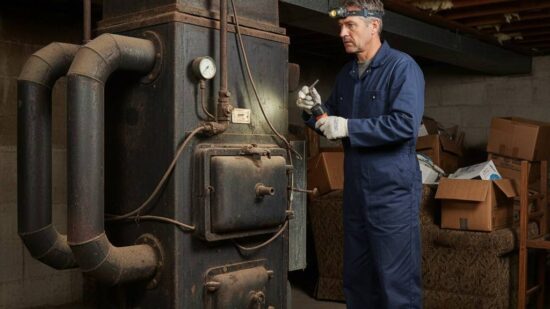

4. Maintain Equipment Proactively

Equipment failures can be a major source of downtime and lost revenue in oilfield operations. Implementing a proactive maintenance program ensures that rigs, pumps, and other critical assets remain in peak condition.

Regular inspections, timely repairs, and proper lubrication schedules can extend the life of equipment and prevent unexpected breakdowns.

For specialized services, such as bottom hole assembly services, ensuring that equipment is maintained and calibrated correctly is vital for achieving smooth operations and reducing delays.

Proactive maintenance reduces emergency repair costs and keeps projects on schedule, directly contributing to higher profitability.

5. Streamline Supply Chain Management

An efficient supply chain is essential for oilfield service companies. Delays in the delivery of parts, chemicals, or equipment can halt operations and inflate costs.

Streamlining supply chain processes—through accurate forecasting, supplier partnerships, and inventory management systems—can significantly improve operational flow.

By maintaining an optimal stock of essential materials and reducing dependency on last-minute shipments, companies can avoid production delays and maintain steady output levels, which ultimately improves profitability.

6. Leverage Data and Analytics

Data is a powerful tool for smarter decision-making. By collecting and analyzing operational data, oilfield companies can identify inefficiencies, predict equipment failures, and optimize processes.

Metrics such as drilling speed, downtime frequency, and fuel consumption can highlight areas for improvement.

Advanced analytics tools also allow companies to model different operational scenarios, helping managers make data-driven decisions that boost productivity while controlling costs. The result is a more responsive, efficient, and profitable operation.

7. Foster a Culture of Continuous Improvement

Finally, cultivating a culture of continuous improvement can have a lasting impact on productivity. Encourage teams to provide feedback, suggest operational enhancements, and adopt innovative solutions.

Rewarding efficiency and problem-solving reinforces positive behaviors and motivates staff to continuously seek ways to optimize performance.

Companies that prioritize continuous improvement are better positioned to adapt to market changes, reduce waste, and maximize profits over time.

Optimizing an oilfield service company requires a multifaceted approach that combines technology, skilled personnel, proactive maintenance, and data-driven strategies.

By embracing these practices, businesses can not only boost productivity but also increase profitability, ensuring long-term success in a highly competitive industry. Smart operations aren’t just about cutting costs—they’re about creating a system that works efficiently, safely, and profitably at every level.