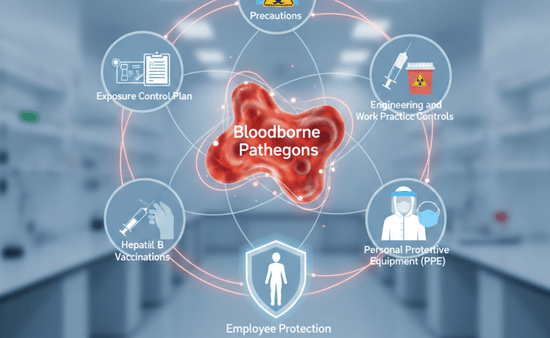

Workplace safety is crucial, particularly in fields where employees face exposure to infectious materials. To address this, the Occupational Safety and Health Administration (OSHA) created the Bloodborne Pathogens Standard (29 CFR 1910.1030). This regulation aims to protect workers from health risks associated with exposure to blood and other potentially infectious materials (OPIM).

Key Requirements of the Standard

OSHA’s Bloodborne Pathogens Standard is comprehensive, detailing the specific measures employers must take to minimize or eliminate occupational exposure. At its core, the standard mandates a multi-faceted approach that includes creating an Exposure Control Plan, implementing universal precautions, using engineering and work practice controls, providing Personal Protective Equipment (PPE), and offering Hepatitis B vaccinations to employees.

Each requirement works together to form a system of safety protocols. Adhering to these requirements helps protect employees from infection and shields employers from significant legal and financial penalties.

Who is Covered Under the Standard?

The standard applies to all employers who have employees with occupational exposure to blood or OPIM. This means any employee whose job duties could reasonably result in skin, eye, mucous membrane, or parenteral (piercing the skin) contact with these materials is covered.

This includes a wide range of professions, not just those in healthcare. While doctors, nurses, and laboratory technicians are obvious examples, the standard also covers:

- Emergency responders (paramedics, police officers, firefighters)

- Morticians and funeral home employees

- Housekeeping staff in healthcare facilities

- Tattoo artists and body piercers

- Anyone providing first aid as a designated part of their job

If your business requires employees to handle or be potentially exposed to blood or OPIM, you are required to comply with this standard.

Training and Education Requirements

Knowledge is the first line of defense. OSHA requires employers to provide annual training to all employees covered by the standard. This training must be conducted by a knowledgeable person who can answer questions, and it must cover essential topics, including:

- An accessible copy and explanation of the OSHA Bloodborne Pathogens Standard.

- An overview of the epidemiology and symptoms of bloodborne diseases.

- Information on how bloodborne pathogens are transmitted.

- An explanation of the facility’s Exposure Control Plan and how employees can obtain a copy.

- Information on how to recognize tasks that may involve exposure.

- Details on the use and limitations of methods that will prevent or reduce exposure, including engineering controls, work practices, and PPE.

- Information on the types, proper use, location, removal, handling, decontamination, and disposal of PPE.

- An explanation of the basis for PPE selection.

- Information on the Hepatitis B vaccine, including its safety, effectiveness, benefits, and the fact that it is offered free of charge.

- Emergency procedures for reporting and responding to exposure incidents.

- Post-exposure evaluation and follow-up procedures.

- Explanations of signs, labels, and color-coding used to identify biohazards.

This training must be provided at no cost to employees and during working hours.

Engineering and Work Practice Controls

Engineering and work practice controls are designed to eliminate or minimize employee exposure by either removing the hazard or isolating the worker from it.

Engineering controls are physical objects used to isolate or remove a hazard. Examples include:

- Sharps disposal containers

- Self-sheathing needles

- Needleless systems

Work practice controls are procedures that reduce the likelihood of exposure by altering the way a task is performed. Examples include:

- Proper handwashing techniques.

- Procedures for handling and disposing of contaminated sharps.

- Prohibiting eating, drinking, and smoking in work areas where there is a potential for exposure.

- Procedures for minimizing splashing, spraying, or spattering of blood or OPIM.

Personal Protective Equipment (PPE)

When engineering and work practice controls cannot eliminate all risk, employers must provide Personal Protective Equipment (PPE) at no cost to employees. PPE acts as a barrier between the worker and the infectious material.

The type of PPE required depends on the task being performed and the anticipated level of exposure. Common types of PPE include:

- Gloves: Must be worn when there is a potential for hand contact with blood, OPIM, mucous membranes, or non-intact skin.

- Gowns, aprons, and lab coats: Protect skin and clothing from contamination.

- Face shields, goggles, and masks: Protect the eyes, nose, and mouth from splashes, sprays, and spatter.

Employers are responsible for ensuring PPE is available, properly used, cleaned, laundered, repaired, and disposed of correctly.

Exposure Control Plan (ECP)

Every employer with covered employees must develop and implement a written Exposure Control Plan (ECP). This plan is the roadmap for how the organization will prevent exposures. The ECP must be reviewed and updated at least annually, and whenever new tasks or procedures affecting occupational exposure are introduced.

The ECP must include:

- A list of job classifications where all or some employees have occupational exposure.

- A list of tasks and procedures where occupational exposure occurs.

- The schedule and method of implementation for each part of the OSHA standard.

- Procedures for evaluating the circumstances surrounding an exposure incident.

The plan must be accessible to all employees.

Housekeeping and Decontamination

Workplaces must be kept in a clean and sanitary condition. OSHA requires a written schedule for cleaning and decontamination of the worksite. This includes:

- Cleaning and decontaminating equipment and surfaces after contact with blood or OPIM.

- Using appropriate disinfectants, such as a solution of bleach and water or an EPA-registered disinfectant.

- Properly disposing of contaminated items, such as PPE and sharps, in designated, labeled containers.

For significant spills or contamination events, specialized services may be required. For instance, businesses can seek out professional biohazard cleaning services in Salt Lake City and other areas to ensure proper decontamination according to all regulations.

Hepatitis B Vaccination

Employers must make the Hepatitis B vaccine available to all employees with occupational exposure. This vaccination series must be offered free of charge, at a reasonable time and place, and after the employee has received the required training.

If an employee initially declines the vaccination, they must sign a declination form. However, they can choose to receive the vaccine at any time later, at no cost, as long as they are still covered by the standard.

Post-Exposure Evaluation and Follow-Up

If an exposure incident occurs, the employer must provide a confidential medical evaluation and follow-up at no cost to the employee. This includes:

- Documenting the route of exposure and the circumstances under which it occurred.

- Identifying and testing the source individual for HBV and HIV, if feasible and consent is obtained.

- Collecting and testing the exposed employee’s blood for HBV and HIV status.

- Offering post-exposure prophylaxis, when medically indicated.

- Providing counseling and evaluating reported illnesses.

Recordkeeping Requirements

OSHA requires employers to maintain several types of records:

- Medical Records: Must be kept for each employee with occupational exposure for the duration of their employment plus 30 years. These records are confidential.

- Training Records: Must be maintained for three years from the date of the training. They should include the dates of training, content of the session, names and qualifications of trainers, and names and job titles of all attendees.

- Sharps Injury Log: Employers with more than 10 employees must maintain a log of percutaneous injuries from contaminated sharps.

Conclusion

Complying with OSHA’s Bloodborne Pathogens Standard is crucial for worker safety. Employers should develop an Exposure Control Plan, provide proper training, and enforce safety measures. Regular updates to the plan ensure effectiveness and alignment with current guidelines, creating a safer workplace.