We have all experienced the frustration of buying a product that looks fantastic on the shelf, only to have it fade, crack, or malfunction within a few months of use. This disappointment is often attributed to “planned obsolescence,” but for high-quality manufacturers, the goal is exactly the opposite.

Creating products that withstand the test of time while maintaining their visual appeal is a complex engineering challenge that separates premium brands from budget alternatives.

Material Selection for Durability and Aesthetics

The foundation of any long-lasting product is the raw material from which it is made. No amount of engineering or surface treatment can fully compensate for a poor choice of substrate.

Manufacturers must balance cost, weight, and workability against the physical properties required for the product’s intended environment.

Understanding Environmental Stressors

Engineers begin by analyzing where the product will live. A component intended for a climate-controlled office has vastly different material requirements than machinery operating on an offshore oil rig. For outdoor applications, UV resistance is paramount.

Standard plastics often become brittle and yellow when exposed to sunlight, leading manufacturers to select UV-stabilized polymers or metals that are naturally resistant to degradation.

Strength-to-Weight Ratios

In industries like automotive and aerospace, durability cannot come at the expense of weight. This has led to the widespread adoption of advanced composites and alloys. For instance, while carbon steel provides immense strength, it is heavy and prone to rust.

Manufacturers might opt for titanium or high-grade aluminum alloys, which offer excellent tensile strength and natural corrosion resistance without the bulk.

The Role of Material Purity

Inconsistencies in raw materials create weak points. High-end manufacturing relies on certified, high-purity materials. In metal casting, impurities can lead to microscopic cracks that propagate over time under stress.

By sourcing higher-grade raw inputs, manufacturers ensure a uniform internal structure, which directly translates to a product that can handle repetitive stress without failing.

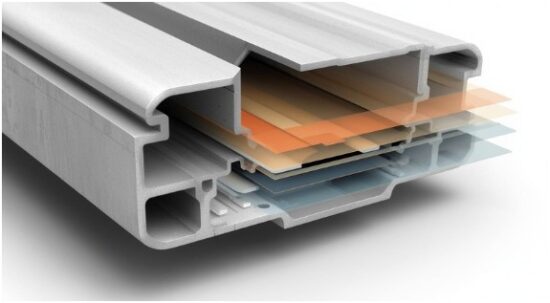

Surface Treatments and Coatings

Once the substrate is formed, it requires protection. Raw materials are rarely left exposed to the elements. Surface treatments act as a shield, preventing environmental factors from reaching the core material while simultaneously providing the color, texture, and finish that define the product’s aesthetic.

The Science of Adhesion

A coating is only as good as its bond to the surface. Manufacturers utilize chemical pretreatment processes, such as phosphating or chromating, to etch the surface of the metal.

This increases the surface area at a microscopic level, allowing primers and topcoats to anchor distinctively. Without this step, even the most expensive paint would eventually peel or flake.

Powder Coating for Resilience

For metal products requiring a hard, durable finish, powder coating has become the industry gold standard. Unlike traditional liquid paint, which contains solvents that evaporate, powder coating in Utah involves applying a dry powder electrostatically and then curing it under heat.

This process allows the powder to flow and form a “skin.” The result is a finish that is much thicker and harder than conventional paint, offering superior resistance to scratches, chipping, and fading. It also provides a uniform look without the drips or running associated with liquid sprays.

Anodizing and Galvanizing

Different metals require different approaches. Aluminum is often anodized—an electrochemical process that thickens the natural oxide layer on the surface. This makes the metal harder than raw aluminum and allows it to be dyed in vibrant, metallic colors that won’t chip because the color is part of the metal itself.

For steel, galvanization (coating with a protective layer of zinc) remains a primary method for preventing rust, serving as a sacrificial anode that corrodes before the steel does.

Design Considerations for Longevity

Durability is not just about what a product is made of, but how it is shaped and assembled. Intelligent design can eliminate failure points before a prototype is even built.

Stress Distribution and Geometry

Sharp corners and abrupt changes in geometry act as “stress risers,” concentrating mechanical force in a small area. Over time, these areas are the first to crack.

Industrial designers use Computer-Aided Design (CAD) and Finite Element Analysis (FEA) to simulate loads and smooth out these transitions. By using fillets (rounded corners) and reinforcing ribs, they distribute stress more evenly across the part.

Modular and Repairable Design

A product’s life is significantly shortened if one broken component renders the whole unit useless. Forward-thinking manufacturers are moving toward modular design principles.

By using standard fasteners instead of permanent glues and ensuring high-wear components (like seals, bearings, or buttons) are accessible, they allow for maintenance and repair. This extends the functional life of the product and maintains its appearance by allowing worn exterior parts to be swapped out.

Thermal Management

Heat is a silent killer of electronics and mechanical parts. Excessive heat degrades batteries, warps plastics, and stresses solder joints.

Designers integrate heat sinks, ventilation channels, and thermal interface materials to dissipate heat effectively. Keeping a product cool during operation is one of the most effective ways to ensure it reaches its expected lifespan.

Quality Control and Testing Procedures

The final step in ensuring longevity is verifying that the manufacturing process worked as intended. Quality Control (QC) is not just a final check; it is a continuous monitoring system.

Accelerated Life Testing

Manufacturers cannot wait ten years to see if a product lasts ten years. Instead, they use Highly Accelerated Life Testing (HALT).

This involves subjecting the product to extreme conditions—rapid temperature cycling, intense vibration, and high voltage—to identify weaknesses quickly. If a product survives the torture chamber of the lab, it is likely to survive normal use in the field.

Environmental Simulation

To test surface finishes, manufacturers use salt spray chambers. These machines blast components with a saline mist to simulate years of coastal corrosion in a matter of days.

They also use UV weathering testers to simulate prolonged sun exposure. These tests ensure that the powder coating or anodizing will maintain its color and protective qualities without chalking or fading.

Tolerance Verification

In mechanical assemblies, loose parts cause vibration, and vibration causes wear. Manufacturers use Coordinate Measuring Machines (CMM) and laser scanners to verify that every part is manufactured within strict dimensional tolerances. This precision ensures a tight fit, reducing internal friction and preventing the “rattle” associated with lower-quality goods.

Conclusion

The difference between a product that lasts a year and one that lasts a decade is in the details: material science, advanced coatings, intelligent design, and strict quality control.

For manufacturers, investing in these areas builds brand reputation. For buyers, understanding these factors helps evaluate a product’s true lifetime value beyond its price tag.