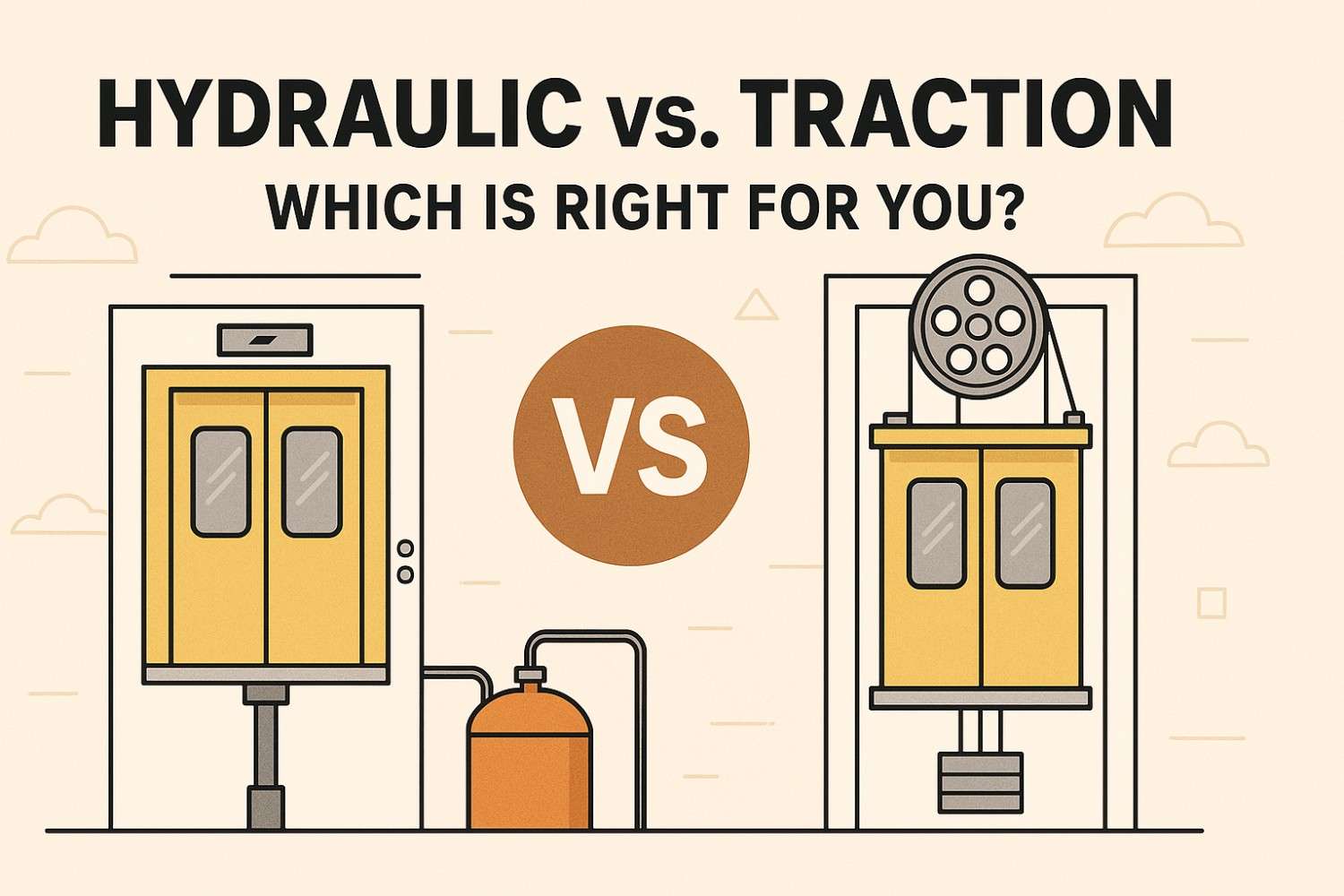

When choosing an elevator, one of the most critical decisions is the lifting mechanism. The two most common types are hydraulic and traction elevators, each with its own features and benefits. Understanding the difference between them is key to selecting a safe, efficient, and cost-effective vertical transportation solution for your building.

Understanding Hydraulic Elevators

Hydraulic elevators operate on a simple yet powerful principle: fluid pressure. They use a piston inside a cylinder to lift the elevator car. An electric motor pumps hydraulic fluid—typically oil—from a tank into the cylinder, which pushes the piston up and raises the car. To descend, a valve releases the fluid, allowing it to flow back into the tank, and gravity gently lowers the car.

How They Work

The core components of a hydraulic elevator system include a pump, a fluid reservoir (tank), a cylinder, and a piston. When a user presses the “up” button, the pump activates and forces the hydraulic fluid into the cylinder. The accumulating fluid pressure pushes the piston upward, lifting the elevator car with it. The descent is even simpler. The system’s controller opens a valve, and the weight of the car and its passengers forces the fluid out of the cylinder and back into the reservoir, causing a smooth downward movement.

Advantages of Hydraulic Elevators

- Cost-Effectiveness: Hydraulic elevators generally have a lower initial purchase and installation cost compared to traction systems. Their mechanical design is simpler, requiring fewer components in the hoistway.

- High Lifting Capacity: The power of hydraulics allows these elevators to lift heavy loads. This makes them an excellent choice for freight elevators or applications where transporting bulky goods is a priority.

- Compact Design: Since the lifting mechanism is located at the bottom of the hoistway in a machine room, there is no need for an overhead machine room, which can save space in the building’s design.

Disadvantages of Hydraulic Elevators

- Slower Speed: Hydraulic systems are typically slower than traction elevators, with speeds usually ranging from 100 to 150 feet per minute. This can lead to longer wait times in buildings with heavy foot traffic.

- Height Limitations: The piston’s length limits the travel height of a hydraulic elevator, making it suitable only for low-rise buildings, generally up to about six stories.

- Environmental Concerns: Traditional hydraulic systems that use in-ground cylinders pose a risk of oil leakage, which can contaminate soil and groundwater. Modern “holeless” designs mitigate this risk, but the potential for leaks in the machine room remains. They also tend to be less energy-efficient, as the motor works against gravity to lift the car.

Common Applications

Given their strengths and limitations, hydraulic elevators are most commonly found in:

- Low-rise commercial buildings (2-6 stories).

- Residential buildings, including single-family homes looking for an elevator for homes in Boise, ID.

- Freight and material handling applications in warehouses and industrial facilities.

- Buildings where initial cost is a primary consideration.

Exploring Traction Elevators

Traction elevators are the standard for mid-rise and high-rise buildings. They use a system of steel ropes or belts, a pulley (also known as a sheave), and a counterweight to move the elevator car up and down the hoistway.

How They Work

In a traction system, the elevator car is attached to steel ropes that loop over a sheave connected to an electric motor. On the other end of the ropes is a counterweight, which weighs roughly the same as the elevator car when it’s filled to 40-50% of its capacity. This balance is crucial. The motor doesn’t have to lift the full weight of the car; instead, it only needs to lift the difference in weight between the car and the counterweight. When the car goes up, the counterweight goes down, and vice versa. The friction—or traction—between the ropes and the sheave is what moves the car.

There are two main types of traction elevators:

- Geared Traction: These use a gearbox to connect the motor and the sheave, which helps control the movement. They are suitable for mid-speed applications, typically up to 500 feet per minute.

- Gearless Traction: In this design, the sheave is directly attached to the motor. This allows for much higher speeds (up to 2,000 feet per minute or more) and a smoother ride, making them ideal for high-rise buildings.

Advantages of Traction Elevators

- High Speed: Traction elevators are significantly faster than hydraulic systems, making them perfect for tall buildings where reducing travel time is essential.

- No Height Restrictions: Because they don’t rely on a piston, traction elevators can serve buildings of any height, from mid-rise structures to the world’s tallest skyscrapers.

- Energy Efficiency: The use of a counterweight balances the load, meaning the motor uses far less energy to move the car. Modern gearless traction systems with regenerative drives can even capture energy during descent and feed it back into the building’s electrical grid.

Disadvantages of Traction Elevators

- Higher Initial Cost: The complexity of the system, including the motor, ropes, and safety equipment, results in a higher purchase and installation cost.

- Complex Installation and Maintenance: Installing a traction elevator is more intricate, and the maintenance requirements are more demanding due to the greater number of moving parts.

- Overhead Machine Room: Traditional traction elevators require a machine room above the hoistway to house the motor and control systems, though modern Machine-Room-Less (MRL) designs integrate these components into the hoistway itself.

Common Applications

Traction elevators are the go-to choice for:

- Mid-rise and high-rise office buildings.

- Hotels and residential skyscrapers.

- Hospitals and airports with high passenger traffic.

- Any building where speed and ride quality are top priorities.

Hydraulic vs. Traction: A Side-by-Side Comparison

| Feature | Hydraulic Elevator | Traction Elevator |

| Speed | Slower (up to 150 ft/min) | Faster (up to 2,000 ft/min) |

| Travel Height | Low-rise (up to 6 stories) | No height limit |

| Initial Cost | Lower | Higher |

| Energy Efficiency | Lower | Higher (especially gearless) |

| Lifting Capacity | Excellent for heavy loads | Standard passenger loads |

| Ride Quality | Generally smooth | Very smooth, especially gearless |

| Installation | Simpler | More complex |

| Environmental | Potential for oil leaks | More eco-friendly |

How to Choose the Right Elevator

Selecting the right elevator depends on a careful evaluation of your building’s needs. Consider these factors:

1. Building Height: This is the most straightforward consideration. For buildings over six stories, a traction elevator is the only viable option. For low-rise buildings, either type could work.

2. Usage and Traffic: How many people will use the elevator, and how frequently? For high-traffic environments like busy office buildings or hospitals, the speed of a traction elevator is necessary to prevent long waits. For a low-traffic residential building, a hydraulic elevator’s slower speed is often acceptable.

3. Budget: If upfront cost is the primary driver, a hydraulic elevator is often the more attractive choice. However, it’s important to consider long-term operating costs. A traction elevator’s energy efficiency may lead to significant savings over the life of the system.

4. Load Requirements: If the elevator will be used to transport heavy goods, such as in a warehouse or for moving furniture in a residential building, a hydraulic system’s superior lifting capacity is a major advantage.

Conclusion

The choice between hydraulic and traction elevators is evolving with technology. MRL traction elevators are now viable for low-rise buildings, offering energy efficiency and space savings. Meanwhile, advancements in hydraulic systems, like biodegradable oils and efficient pumps, address their traditional drawbacks.